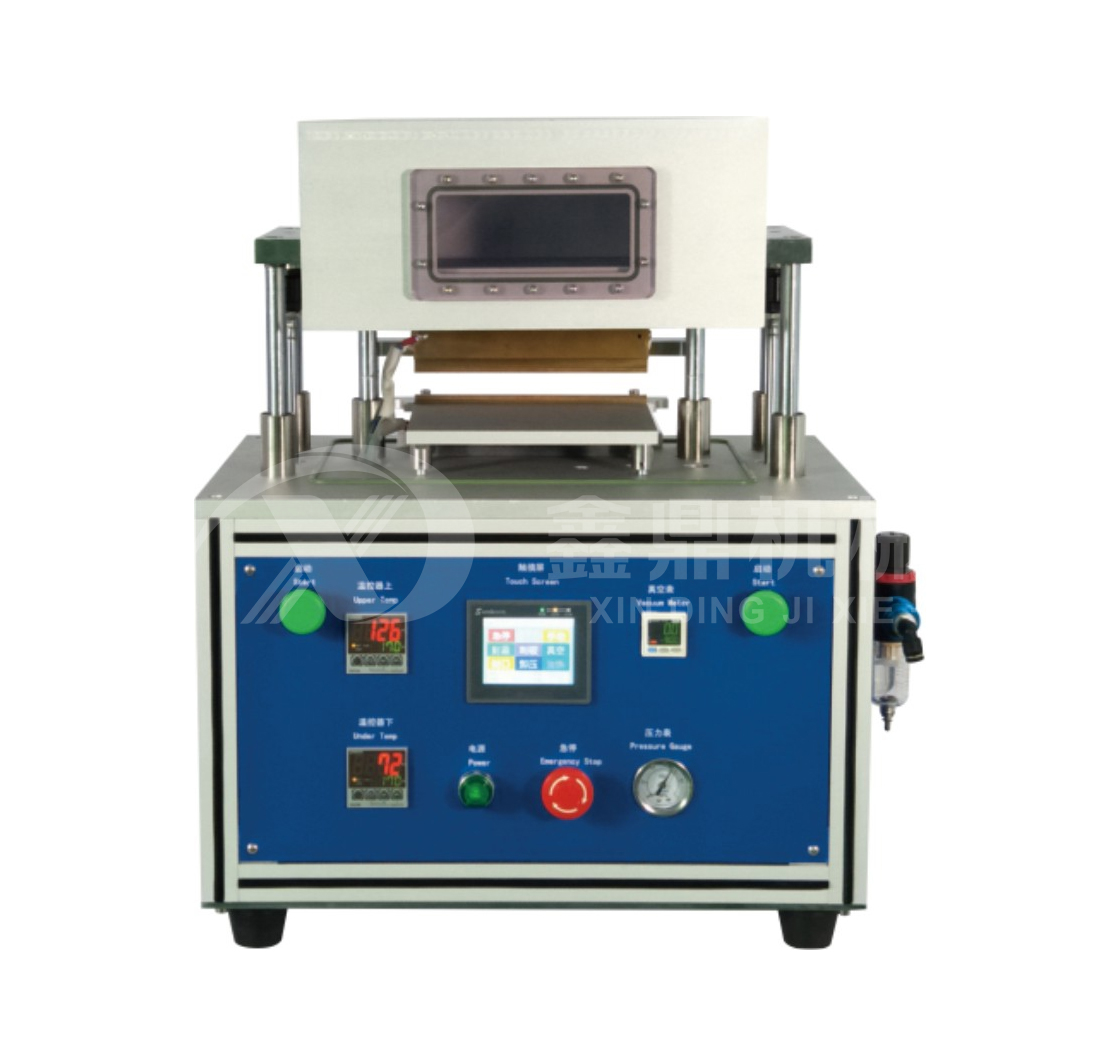

Brand: Shenzhen Xinding Machinery

Product Name: XD-YFJ200 secondary vacuum packaging machine

Product use: The secondary vacuum packaging machine is mainly used for vacuum heat sealing of flexible packaging batteries; the machine automatically completes the battery by controlling the vacuum chamber and the pneumatic heat sealing assembly.

Introduction: A heating type sealing device for the top and side of flexible packaging lithium-ion batteries.The device heats the upper and lower heads through a resistive heating tube to enable the aluminum plastic film to be fused at a set pressure.

Features: Cylinder drive head for heat sealing, sealing pressure regulating valve control, excellent sealing effect; compact and lightweight, can be conveniently placed in the glove box ; compressed air or inert gas cylinder for two ways, compressed air exhaust The external connection can prevent the atmosphere of the glove box from being damaged; the resistance heating tube heats the sealing head, and the temperature of the upper and lower sealing heads is precisely and independently controlled; the soft-to-hard sealing method and the pressing and holding time are manually controlled; the countertop design and the operation platform are arranged, and the operation is safe and convenient;

Product parameters:

| power supply | Voltage single phase 220VAC±10% (customizable 110VAC), frequency 50Hz/60Hz, power 1KW |

| Gas source | 0.5-0.8MPa compressed air |

| Edge length | Max. 160mm |

| Edge width | 3.5mm (can be customized) |

| Edge thickness | 0~0.5mm |

| Upper mold temperature | Max. 250°C, 200°C recommended |

| Lower mold temperature | Max. 250°C, 180°C recommended |

| Sealing time | Manual control, recommended to use 2~3s |

| Installation size | L365mm*W245mm*H340mm |

| weight | About 30Kg |

Warranty: one year warranty, lifetime maintenance

Features:

The cylinder drive head is heat-sealed, the sealing pressure regulating valve is controlled, and the sealing effect is excellent; the compact and light, can be conveniently placed in the glove box ; the compressed air or the inert gas bottle can be supplied in two ways, and the compressed gas exhaust can be externally connected. Prevent the atmosphere of the glove box from being damaged; the resistance heating tube heats the sealing head, the temperature of the upper and lower sealing heads is precisely and independently controlled; the soft-to-hard sealing method, the pressing and holding time manual control; the countertop design, the configuration operation platform, the operation is safe and convenient;

| power supply | Voltage single phase 220VAC±10% (customizable 110VAC), frequency 50Hz/60Hz, power 1KW |

| Gas source | 0.5-0.8MPa compressed air |

| Edge length | Max. 160mm |

| Edge width | 3.5mm (can be customized) |

| Edge thickness | 0~0.5mm |

| Upper mold temperature | Max. 250°C, 200°C recommended |

| Lower mold temperature | Max. 250°C, 180°C recommended |

| Sealing time | Manual control, recommended to use 2~3s |

| Installation size | L365mm*W245mm*H340mm |

| weight | About 30Kg |

0755-27806324 Email:17307550303@139.com

0755-27806324 Email:17307550303@139.com

Mr Guo:17307550303 For the record number: guangdong ICP for 19078327

Address: shenzhen baoan district xinqiao street zhuang village

new two community professional Fang Yongfa technology park five layer building workshop A

Mobile station