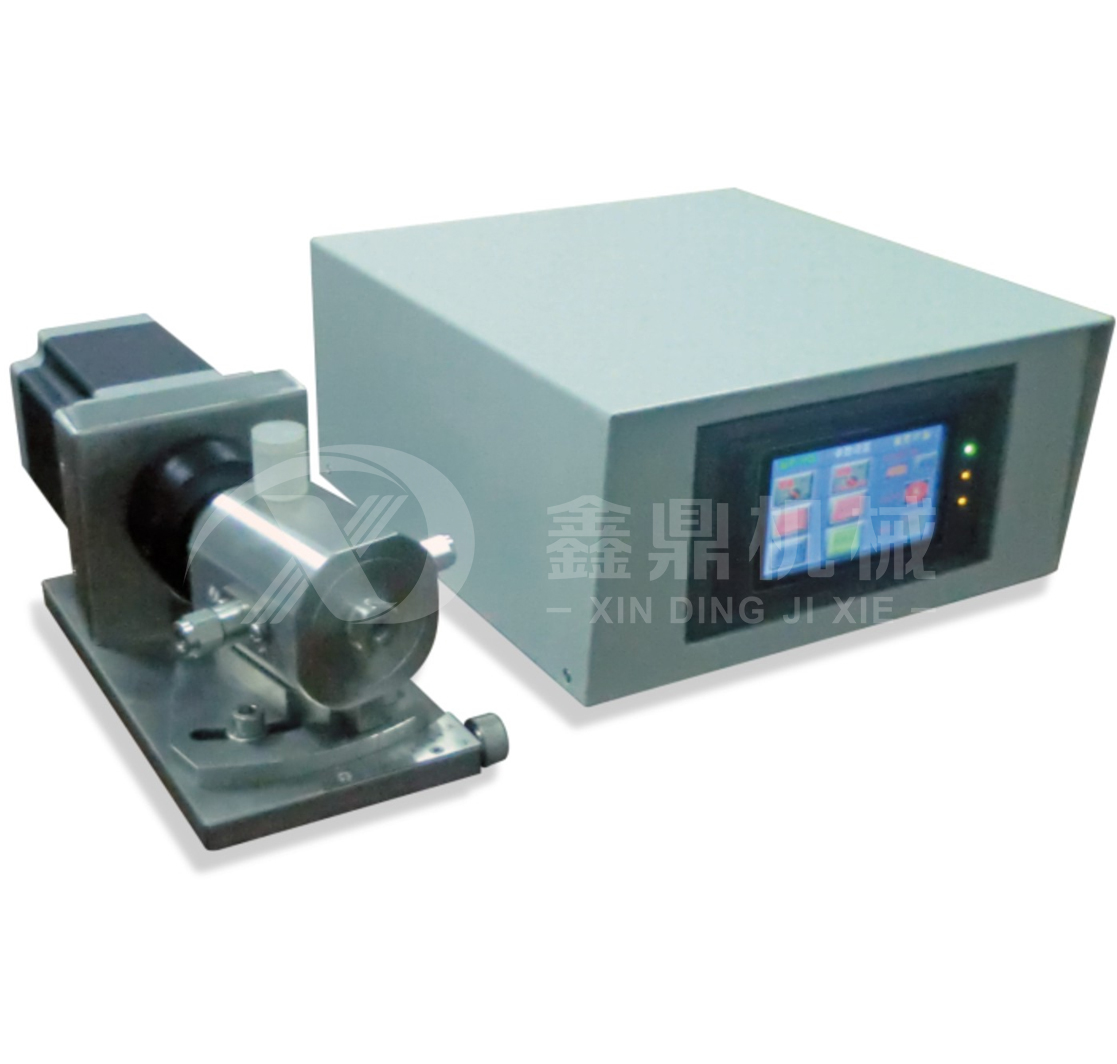

Brand: Shenzhen Xinding Machinery

Product Name: XD-ZY40ML Injection Pump

Uses : Wide applicability, using rotary valve structure, from low viscosity (<10000CPS), medium viscosity (10000~100000CPS), to high viscosity (>100000~500000CPS);

| main feature | 1. High precision, the accuracy of liquid injection is less than 0.25% |

| 2. With counting function, the maximum liquid injection per second is 0~40ml/sec, and the liquid injection volume is adjustable; | |

| 3. Wide applicability, using rotary valve structure, from low viscosity (<10000CPS), medium viscosity (10000~100000CPS), to high viscosity (>100000~500000CPS); | |

| 4. Anti-corrosion, special high wear-resistant ceramic pump head, long service life, imported components in key parts, anti-corrosion, reliable and durable; | |

| 5. It is easy to use, avoiding the phenomenon that the one-way valve type liquid injection pump is easy to generate bubbles; | |

| 6. Compared to maintenance, it is very simple, saving customers a lot of maintenance costs and labor costs; | |

| 7. Control mode, external PLC can be automatically controlled, touch screen control, or external foot switch can be manually operated; | |

| 8. Low noise: As long as the motor drive is installed, it is properly lubricated and the noise decibel can be lowered to a very low level. | |

| 9. High operability: friendly man-machine interface, it can easily realize single step and continuous operation of the liquid injection pump. In addition, an external I/O interface is provided, which can be driven by an external signal to drive the infusion pump; | |

| 10. Anti-pollution, adopting rotary valve structure, no dynamic sealing ring, easy to clean, can be used for aseptic filling, meet the requirements of food, pharmaceutical and industry, and is specially tailored for scientific research laboratories and battery manufacturers; |

Warranty: one year warranty, lifetime maintenance

| main feature | 1. High precision, the accuracy of liquid injection is less than 0.25% |

| 2. With counting function, the maximum liquid injection per second is 0~40ml/sec, and the liquid injection volume is adjustable; | |

| 3. Wide applicability, using rotary valve structure, from low viscosity (<10000CPS), medium viscosity (10000~100000CPS), to high viscosity (>100000~500000CPS); | |

| 4. Anti-corrosion, special high wear-resistant ceramic pump head, long service life, imported components in key parts, anti-corrosion, reliable and durable; | |

| 5. It is easy to use, avoiding the phenomenon that the one-way valve type liquid injection pump is easy to generate bubbles; | |

| 6. Compared to maintenance, it is very simple, saving customers a lot of maintenance costs and labor costs; | |

| 7. Control mode, external PLC can be automatically controlled, touch screen control, or external foot switch can be manually operated; | |

| 8. Low noise: As long as the motor drive is installed, it is properly lubricated and the noise decibel can be lowered to a very low level. | |

| 9. High operability: friendly man-machine interface, it can easily realize single step and continuous operation of the liquid injection pump. In addition, an external I/O interface is provided, which can be driven by an external signal to drive the infusion pump; | |

| 10. Anti-pollution, adopting rotary valve structure, no dynamic sealing ring, easy to clean, can be used for aseptic filling, meet the requirements of food, pharmaceutical and industry, and is specially tailored for scientific research laboratories and battery manufacturers; |

0755-27806324 Email:17307550303@139.com

0755-27806324 Email:17307550303@139.com

Mr Guo:17307550303 For the record number: guangdong ICP for 19078327

Address: shenzhen baoan district xinqiao street zhuang village

new two community professional Fang Yongfa technology park five layer building workshop A

Mobile station