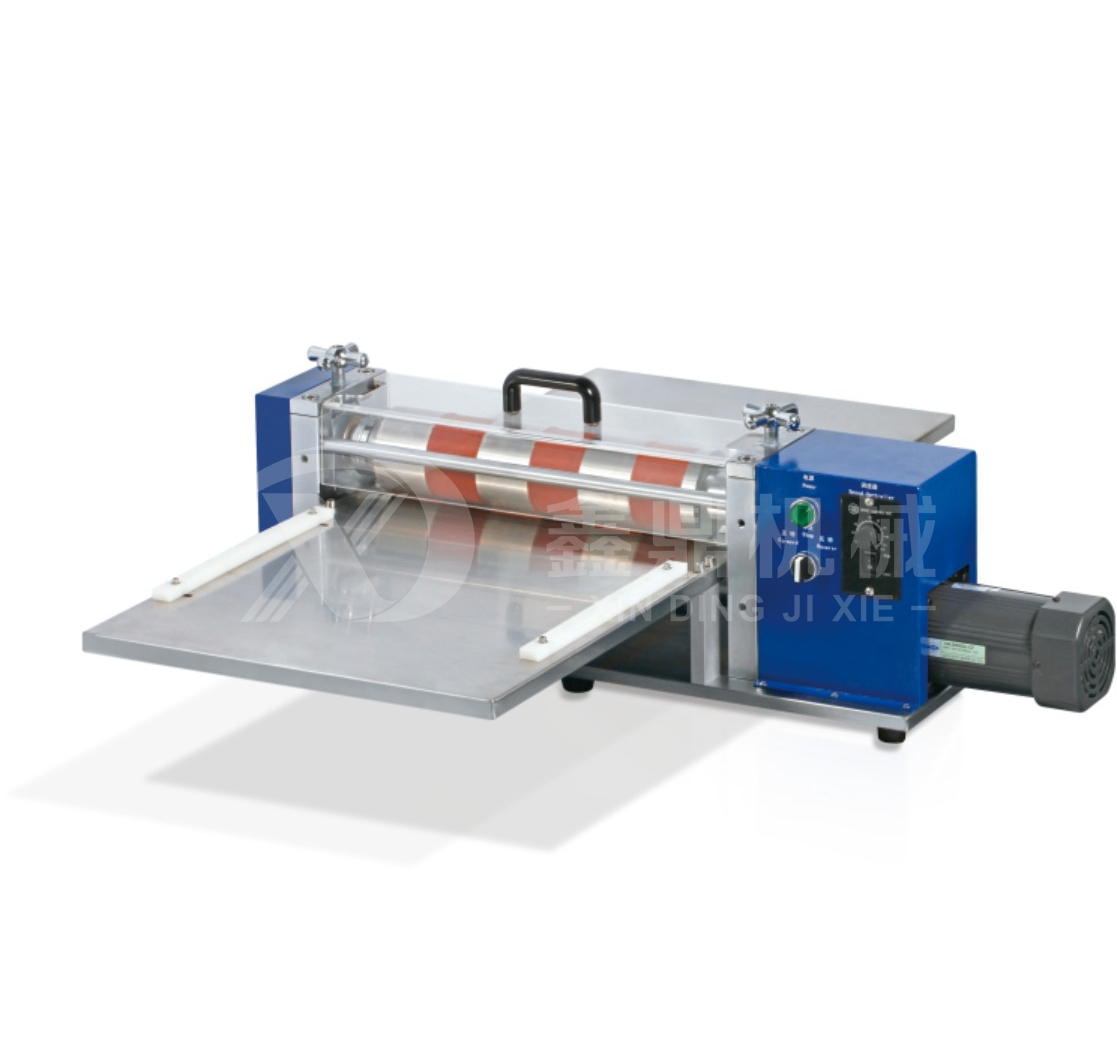

Brand: Shenzhen Xinding Machinery

Product Name: XD-FTJ300 electric slitting machine manufacturers

Product use: It is mainly used for the rolling and slitting of positive and negative electrodes after coating of lithium ion battery. It is divided by a gapless knife, and the edge of the slice is neat to ensure dimensional accuracy.

Introduction: The electric slitting machine can be applied to the precise slitting process of positive and negative electrodes of lithium ion batteries. Sheet feeding, upper and lower round knife slitting, electric drive, slitting width can be adjusted according to the adjustment spacer.

Features: sheet feeding, upper and lower round knife cutting method; ultra-fine alloy tungsten steel blade, good cutting effect, long service life; wide range of thickness of cutting material, accurate adjustment of the amount of knife; motor drive, The feeding guide is arranged, the slitting burr is small; the cutting width can be changed by the spacer sleeve adjustment, and the alternate cutter shaft can also be configured; the open cutter shaft is fixed, the device has good integrity and is convenient to operate;

Product parameters:

| power supply | Voltage single phase 100~240VAC±10%, frequency 50Hz/60Hz, power 100W, less than 4Ω grounding |

| Use environment | Recommended ambient temperature 25±3°C, humidity 30~90RH, no vibration and electromagnetic interference |

| Striping method | Monolithic roll cutting |

| Cutter type | Upper and lower round knife |

| Slitting blade | Ultrafine alloy tungsten steel, diameter Φ100mm |

| Strip width | Adjustment range 20~230mm, can be customized to 20~280mm |

| Width adjustment | Replacement spacer adjustment, standard 56/56/58/58 four |

| Cut thickness | 100 ~ 300µm |

| Burr condition | ≤25μm |

| Eat a knife | Adjustable from 0.2~0.4mm, dial indicator display |

| Slitting speed | Max. 4m / min |

| Installation size | L870mm*W970mm*H450mm |

| weight | 68KG |

Features:

Sheet-shaped feeding, upper and lower round knife cutting method; ultra-fine alloy tungsten steel blade, good cutting effect, long service life; wide range of thickness of cutting material, precise adjustment of the amount of knife; motor drive, configuration Material guiding, small slitting burr; cutting width can be changed by spacer sleeve adjustment, and can also be configured by means of spare cutter shaft; open cutter shaft is fixed, the equipment is good in integrity and convenient to operate;

| power supply | Voltage single phase 100~240VAC±10%, frequency 50Hz/60Hz, power 100W, less than 4Ω grounding |

| Use environment | Recommended ambient temperature 25±3°C, humidity 30~90RH, no vibration and electromagnetic interference |

| Striping method | Monolithic roll cutting |

| Cutter type | Upper and lower round knife |

| Slitting blade | Ultrafine alloy tungsten steel, diameter Φ100mm |

| Strip width | Adjustment range 20~230mm, can be customized to 20~280mm |

| Width adjustment | Replacement spacer adjustment, standard 56/56/58/58 four |

| Cut thickness | 100 ~ 300µm |

| Burr condition | ≤25μm |

| Eat a knife | Adjustable from 0.2~0.4mm, dial indicator display |

| Slitting speed | Max. 4m / min |

| Installation size | L870mm*W970mm*H450mm |

| weight | 68KG |

0755-27806324 Email:17307550303@139.com

0755-27806324 Email:17307550303@139.com

Mr Guo:17307550303 For the record number: guangdong ICP for 19078327

Address: shenzhen baoan district xinqiao street zhuang village

new two community professional Fang Yongfa technology park five layer building workshop A

Mobile station